Double Glazed Sealed Units - Order Online

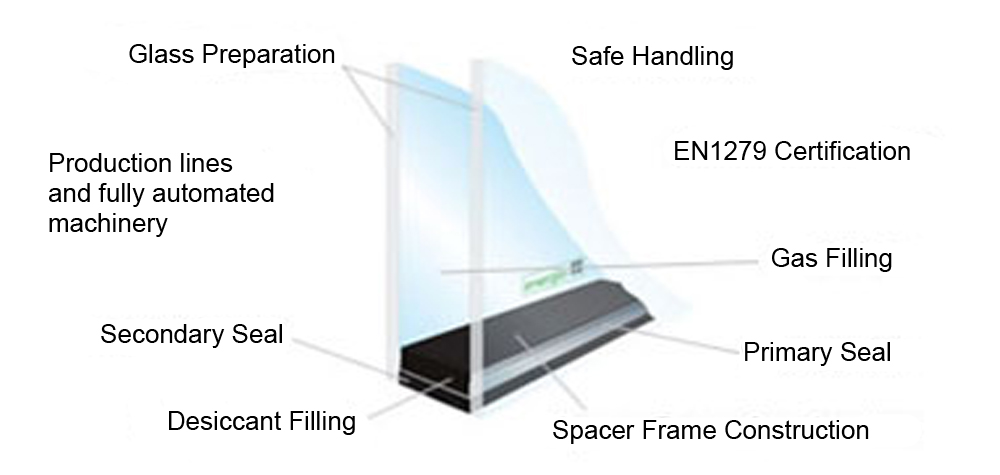

A sealed unit is made with two panes of glass which are separated with a spacer frame made from tube or foam spacer (tube can be bent or cut and corner keyed). The spacer frame is fixed onto the two panes of glass with a primary sealant. A spacer tube is filled with desiccant on two to four sides of the frame (foam spacer is manufactured with a desiccant compound included) and then a secondary sealant is applied to the back of the spacer to seal the unit. Our sealed units can also be filled with Argon gas to improve their thermal efficiency.

Local Glass supply double glazed sealed units to contractors and glaziers which are used in doors, windows, conservatories. We offer many customization options to make ordering replacement sealed units as easy as possible.

40,000 SEALED UNITS EVERY WEEK

Our sealed units are manufactured by Glass Systems. The largest independent IGU manufacturer n the UK with a number of plants in Wales, Scotland and England, Glass Systems manufacture our laminated, toughened and decorative glass units for Trade, Commercial and New Builds.

See Also

Aluminium Bifold Doors

Aluminium bi-fold doors are the best product on the market for opening homes to the garden and mergi ...

Read MoreUpvc French Doors

On a warm summer’s day, there’s nothing quite like throwing open your French doors and l ...

Read More

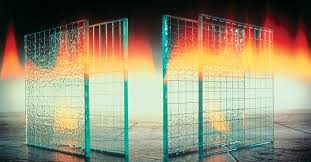

Fire Rated Glass

Local Glass is a nationwide supplier of fire rated and other specialist glass, tailored to your need ...

Read More